pulverizing concrete pavement machines

Road Reclaimers Cat Caterpillar

Road Reclaimers. Cat road reclaimers pulverize the asphalt layer and mix it with the underlying base to stabilize deteriorated roadways. The reclaimers can add asphalt

اObtener precio

WIRTGEN Products Wirtgen

Asphalt and concrete pavements can be cost-effectively removed with cold milling machines. The range of applications extends from the complete removal of asphalt and concrete to the layer-by-layer removal and

اObtener precio

Portland Cement Concrete Pavement Pulverizing Equipment

Concrete can be pulverized by removing a large slab of concrete and hauling it to a central plant where the slab size is reduced (often with a hydraulic hammer) to a size suitable for

اObtener precio

What is Asphalt Pulverizer? - Colorado Pavement Solutions

Asphalt pulverizing is the process of grinding up both the top layer of asphalt and its underlying aggregate to create a new base surface for fresh asphalt. During pulverizing, a machine with rotating blades reaches

اObtener precio

3 Asphalt Processes to Know: Milling, Pulverizing and

Pulverizing is similar to milling, in that a huge machine drives along the roadway, ripping up existing asphalt. Unlike milling, pulverization is the first stage in reusing asphalt to re

اObtener precio

Pulverizer Attachments Concrete and Rock Crusher

Our concrete pulverizers are machines that crushes demolished material between one fixed and one moving jaw to reduce the particle size and to separate iron from other material. We have two main categories of

اObtener precio

Road Construction Milling Pulverizing - Team Elmer's

Milling Mill concrete, asphalt, or cut gravel to grade with our milling and widener equipment. Where full-depth reclamation (pulverization) turns asphalt into a gravel-like material,

اObtener precio

Rental Equipment for the Paving Industry The Cat Rental Store

Our more than 1,300 global locations feature a broad selection of paving rental equipment such as: Asphalt pavers: Use these machines to lay and compact hot asphalt on roads, driveways and other surfaces. Cold planers: These asphalt milling machines perform the vital function of removing concrete or pavement from road surfaces.

اObtener precio

Road Construction Milling Pulverizing - Team Elmer's

After the evaluation, the pulverizing machine will crush and blend the existing pavement and some of the underlying material. This eliminates deep cracks that can ultimately lead to reflective cracking. Compaction and Initial Grading Following pulverization, the material will be compacted with a pad foot roller.

اObtener precio

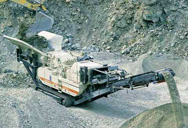

Cold milling Technology Wirtgen

Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. In doing so, they create a level foundation with the specified width and depth that is required for paving new surface layers of uniform thickness. When pavements are milled in layers, the milled material can be separated and selectively recovered ...

اObtener precio

Best Practices for Milling For Construction Pros

April 1, 2014. The asphalt milling machine — also known as a cold planer, pavement planer, pavement recycler, or roto-mill — is a construction machine used to remove bituminous pavement or ...

اObtener precio

DESIGN AND CONSTRUCTION GUIDELINES FOR FULL DEPTH

Preservation of the environment. Conservation of energy. Less user delay. Full depth reclamation (FDR) has been defined (Kandhal and Mallick (1997)) as a recycling method where all of the asphalt pavement section and a predetermined amount of underlying subbase material are treated to produce a stabilized base course.

اObtener precio

Concrete Pulverizer Concrete Crusher Attachment Kenco

CONCRETE PULVERIZER. THIS CONCRETE CRUSHING MACHINE IS A TOOL DESIGNED FOR CONTROLLED DEMOLITION AND RECYCLING OF CONCRETE SLABS, WALLS, BRIDGE DECKS, AND MORE! The Kenco concrete pulverizer jaw requires no hydraulics for it to operate. The bucket cylinder of this concrete processor for excavator

اObtener precio

Pulverizing Concrete Concrete Construction Magazine

2001.6.15 A.: We are not aware of an ultrasonic device that can demolish concrete, although we've been told that such a device was being developed and was demonstrated at World of Concrete several years ago. Perhaps the best method for your application would be the use of hydrodemolition. This demolition process is frequently used on bridges and

اObtener precio

Reclaimed Asphalt: An Alternative Road Sub-base Material

2022.9.16 There are four techniques for removing asphalt concrete for reuse: cold in-place recycling, hot in-place recycling, hot in-plant recycling, and. full-depth reclamation. The full-depth reclamation technique is usually used for recycling asphalt cement for reuse as a sub-base material. This FDR technique has grown in popularity over the past decade.

اObtener precio

Portland Cement Concrete Pavement Pulverizing Equipment

Econocrete or lean concrete section made with recycled PCC was placed in California in 1975, and Iowa placed the first PCC pavement made from an old crushed PCC in 1976. The first large-scaled job using recycled PCC as an aggregate for asphalt concrete occurred in Texas in 1969. Concrete pavement recycling became an alternative pave

اObtener precio

How to Perform Base Stabilization - AsphaltPro Magazine

The depth at which you are stabilizing will determine the size of roller required. Typically, base stabilization ranges from 6 to 14 inches. “Our stabilizers will mix up to 24 inches deep, but you can only process how deep you can compact,” White said. “Most contractors’ rollers can compact around 10 to 12 inches.”.

اObtener precio

Energy-harvesting concrete for smart and sustainable

2021.7.19 Light-emitting properties. Light-emitting concrete has various optional colors and only needs to be fully charged in natural light for 10 min to be able to glow for 12 h or more in the dark, as shown in Fig. 3b, c [26, 27].There are two main approaches to fabricate light-emitting concrete, namely by replacing ordinary aggregates with luminous

اObtener precio

What is Cold Milling? Paving the Way for Replacement

2020.8.31 How it works on asphalt and concrete is we bring in our cold planer: an asphalt milling machine that subtracts pavement or concrete from driving surfaces. It’s an impressive piece of engineering: the rotary cutting drum is stored in protective housing, designed with replaceable carbide bits (or teeth) that spiral in from the edges to push the

اObtener precio

Pavement Manual: Full Depth Reclamation/Recycling (FDR)

Section 5: Full Depth Reclamation/Recycling (FDR) This rehabilitation procedure entails pulverizing the old pavement structure, blending in a stabilizing agent, compacting, adding additional material, and resurfacing. This procedure is meant to address deep structural problems ranging to depths as great as 12 in. in the existing structure.

اObtener precio

Best Practices for Full-Depth Reclamation Using Asphalt Emulsions

Because FDR includes both the existing pavement, base, and, sometimes, the subgrade, the structural section must be known before construction begins to be sure there is enough material available to provide an adequate section for the rehabilitated pavement, and to be sure the existing pavement will support the FDR train of equipment.

اObtener precio

Full Depth Reclamation - Institute for Transportation

2020.3.5 By pulverizing the existing asphalt pavement and the underlying materials to build and strengthen the ... or crushed concrete. The existing roadway geometry, including curb heights and bridge elevations may limit the ... These liquids can be blended into the reclaimed material through the reclaiming machine’s

اObtener precio

Full Depth Recycling - Foamed Asphalt (FDR-FA) Caltrans

Full Depth Recycling-Foamed Asphalt is an on-grade method of pavement rehabilitation that consists of pulverizing the existing asphalt concrete pavement and a portion of the underlying granular base to a maximum depth of 12 inches, mixing and stabilizing the recycled section with a foamed paving-grade asphalt, grading and compacting the

اObtener precio

Guide to FULL-DEPTH RECLAMATION (FDR) - Cement

National Concrete Pavement Technology Center Institute for Transportation, Iowa State University: 2711 South Loop Drive, Suite 4700 Ames, IA 50010-8664: 10. Work Unit No. (TRAIS) ... Pulverizing 66 Grading 69 Cement Placement 70 Dry Cement Placement 70 Slurry Cement Placement 70 Mixing 70 Compaction and Final Grading 71 Curing 72:

اObtener precio

What is Asphalt Pulverizer? - Colorado Pavement Solutions

Asphalt Pulverizer Process. Asphalt pulverizing is the process of grinding up both the top layer of asphalt and its underlying aggregate to create a new base surface for fresh asphalt. During pulverizing, a machine with rotating blades reaches anywhere from 2 to 12 inches down to pulverize different layers of asphalt into one even mix.

اObtener precio

ARCHIVED: Chapter 1 - 98042 - Recycling - Sustainability

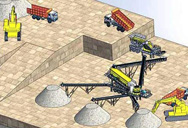

2022.10.21 The process includes pulverizing the existing pavement, sizing of the RAP, application of recycling agent, placement, and compaction. The use of a ... Figure 1-6 shows a typical CIR operation with a milling machine, a crusher and screening plant ... J.A. Epps. Cold-Recycled Bituminous Concrete Using Bituminous Materials, NCHRP ...

اObtener precio

Pulverizing Asphalt Pavement - Constructed items general

2007.9.7 Foamed asphalt uses hot (>100 deg C) liquid asphalt and water. The water expands in to steam, foaming the asphalt and helping it coat the particles better. Cement will work at higher %fines than asphalt, but if you use too much, you will get shrinkage cracks in your subbase that will reflect up through the new top course.

اObtener precio>> Next: Tipo De Ahorro De Energia Wet Molino De Bolas

Mas noticias

- cancion de la barra en la propaganda de molino

- concentración de mineral de hierro

- molinos domsticos de hojas secas en ecuador

- producción de laminación ingenierocanada

- Horno Rotatorio Partes

- precio de venta más barato de maquinaria trituradora de paja

- jigs clasificador de minerales marca denver en peru

- proceso de carbón de importación y distribución de la minería

- Procedimiento De Molinos De Dos Y Tres Rodillos

- trituradora de piedra china máquina acústica en amravati

- informacion sobre piedra de moler

- equipos de molienda de mineral usado

- Trituradora de piedra Consumo

- mill lumber with chainsaw

- la metalurgia y el tratamiento de mineral de molino de sello

- Se utiliza de plastico pp trituradoras

- molinos de harina de China (continente) molino de harina

- Diorite chancadora de piedras para la venta

- trituradora de piedra panwar unidad dos

- separador polvo mineral

- forma eficiente de procesar el mineral de cobre

- mineria de oro a pequena escala de equipos de mineria en ghana

- grado de absorcion de las piedras para triturar

- trituradora de piedra para la mineria de oro

- descripcion de la operacion trituradora de cono

- moler de pulverizadores montana en mexico

- materiales de quimica

- trituradora móvil y3s1848

- extracción de carbón malasia

- tons small capacity steel slag crushers